Stainless Steel Palm Disc Oil Separator Machine Two Phase Saparation

Palm Oil Disc Separator Machine

,Two Phase Oil Disc Separator

,Stainless Steel Palm Oil Disc Separator

Basic Properties

Trading Properties

Stainless Steel Palm Oil Disc Separator Machine Two-Phase or Three Phase saparation Factory Direct Sales

1.Product description

DHZ separator is the equipment which special for oil refining that is of high speed, stable, hermetic, efficient and fully automated. All parts & components contacting materials are made of stainless steel, can effectively minimize chemical reaction between the materials to be separated and part surface contacted. The separated light and heavy phase materials will be output by two centripetal pumps of different sizes. This machine is fed upper, so it has very low inlet pressure for materials. The driving of the separator employs hydraulic coupler and a pair of helical step-up gears, power is transmitted by liquid, so it can step up steadily and have overload protection.

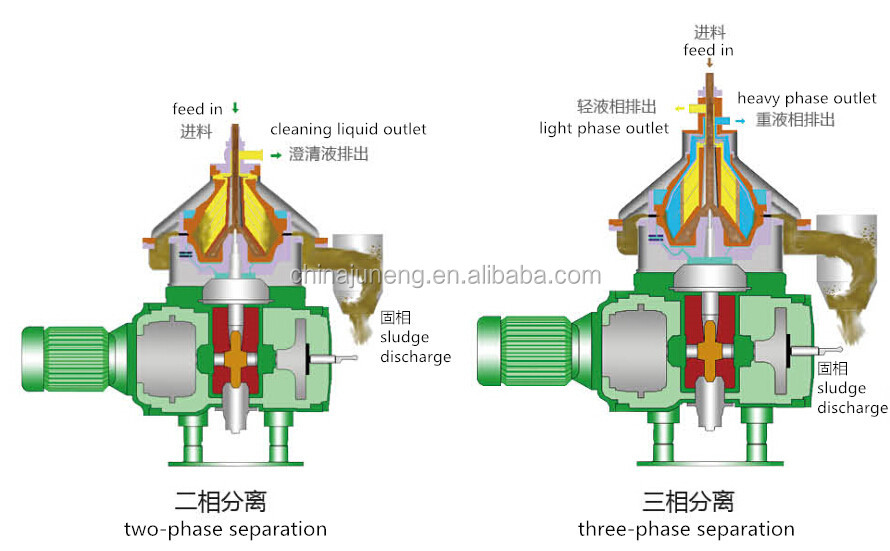

2.Working principle

The materials are transmitted to theheart parts of this machine, the insideof the drum. Under the action of strongcentrifugal force, the materials(mixedliquid) pass through the intervals of agroup of disk pieces bundles, and then,regarding the neutral hole of the diskpieces as the interface, the liquid withhigher density(heavy phase)movesoutward the neutral hole along the diskpieces, among which, the heavy residuesaccumulate in the sediment area, and the heavy phase flows to the large centripetalpump. The liquid with lower density (lightphase)moves inward and upward along thedisk pieces wall and gathers in the smallcentripetal pump. The heavy phase andlight phase output by the large centripetalpump and small centripetal pumprespectively.

1. Soybean, Rapeseed, sunflower seed, cotton seed

2. Palm oil, Coconut oil, linseed oil

3. Peanut , Corn Germ , Rice bran oil

4. Special oil, such as sesame oil, orange peel oil, safflower oil and so on

Core capacity

1. Degumming

2. Deacidification

3. Dewaxing

4. Fractionation

5. Water washing

6. Squeezed oil clarification

7. Lecithin deoiling

8. Frying oil refining

Juneng Group is a large scale manufacturer of industrial products in China. This group principally engaged with the in-house research & development as well as manufacturing of various industrial filters, separators , centrifuges and pumps.

The Company is proud to be the leader in such industry with approximately 90% domestic market share in Oils & Fats industry, Chemical industry, Pharmaceutical industry, Beverage industry, Petrol-chemical industry, and now is one of the well-known producers and suppliers in World .

The Company now has its three production bases with a total capacity of 280,000 square meters in Nanjing city and Yixing City , permanent workforces not less than 1500 people and the production line is well equipped with more than 2000 inits of advanced production equipment and test Instrumentation .

Our Company employs a team of well-trained professional, adopts advance ERP production management model in-cooperation with state-of-the-art apparatus and processes for manufacturing all kinds of filters, separators, centrifuges amd pumps.

Usually it is coverd with plastic film to prevent dust and moisture, then fixed in the seaworthy wooden case. The spare parts and related dovuments will be sent together with the machine.