Fully Automated Disc Oil Separator Machine Two Phase High Speed Stable Hermetic 150T/D

fully automated disc oil separator machine

,Hermetic disc oil separator

,150T/D disc oil separator

Basic Properties

Trading Properties

Two Phase high speed, stable, hermetic, efficient and fully automated disc oil separator machine

1.Product description

DHZ separator is the equipment which special for oil refining that is of high speed, stable, hermetic, efficient and fully automated. All parts & components contacting materials are made of stainless steel, can effectively minimize chemical reaction between the materials to be separated and part surface contacted. The separated light and heavy phase materials will be output by two centripetal pumps of different sizes. This machine is fed upper, so it has very low inlet pressure for materials. The driving of the separator employs hydraulic coupler and a pair of helical step-up gears, power is transmitted by liquid, so it can step up steadily and have overload protection.

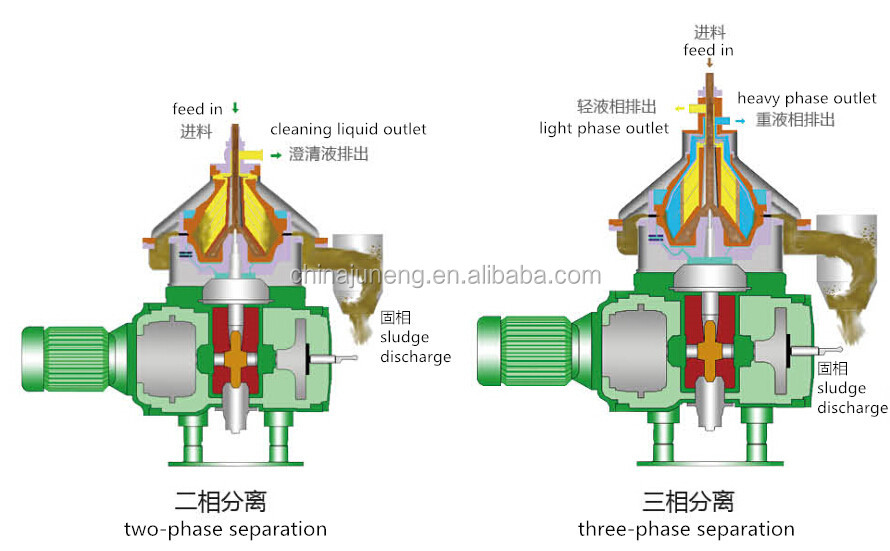

2.Working principle

The separated material will be input into the heart of the separator, i.e. the drum. By the strong centrifugal force field, the material (hybrid liquid) passes the separation partition consists of disk string, by taking the neutral holes in disk as the separating surface, the liquid in higher specific gravity (heavy phase) will move outward the neutral holes along disk wall, and the heavy residue will accumulate at the residue-settling area, and the soap residue will flow toward the big centripetal pump. The liquid in lower specific gravity (light phase) will move inward and upward along disk wall, then assemble at the small centripetal pump. The heavy and light phase will be output separately by small and big centripetal pump.

4.Technical data

5.Production process

Separator process workshop

Drum processing

Process center

Ultrasonic testing

Dynamic balancing test

Assembling

1. Soybean, Rapeseed, sunflower seed, cotton seed

2. Palm oil, Coconut oil, linseed oil

3. Peanut , Corn Germ , Rice bran oil

4. Special oil, such as sesame oil, orange peel oil, safflower oil and so on

7.Test & Inspection

QA & QC / Test

1. Material Test Report 6. Spare Parts Inspection

2. Magnetic Particle Examination 7. Nondestructive Examination

3. Metallographic Analysis Sampling 8. Dynamic Balancing Test

4. Liquid Penetrant Examination 9. Radiographic Examination

5. Over Speed Test 10. Performance Test

Juneng Group is a large scale manufacturer of industrial products in China. This group principally engaged with the in-house research & development as well as manufacturing of various industrial filters, separators , centrifuges and pumps.

The company has a comprehensive scientific research, testing and testing center. It has more than 300 sets of testing equipment. All kinds of tests, analysis and evaluation methods are complete, equipment and instruments are advanced, and the inspection personnel have a higher level of business. Quality control is carried out in several links such as raw materials, finished products and products before leaving factory, so as to ensure that the products are qualified.