| Brand Name: | Juneng |

| Model Number: | DHKY470 |

| MOQ: | 1 set |

| Price: | USD23000-150000/set |

| Delivery Time: | 50 work days |

| Payment Terms: | L/C, T/T |

Disc separator 100~150T/D widely used for degumming, desoaping and water washing in vegetable oil continuous refining

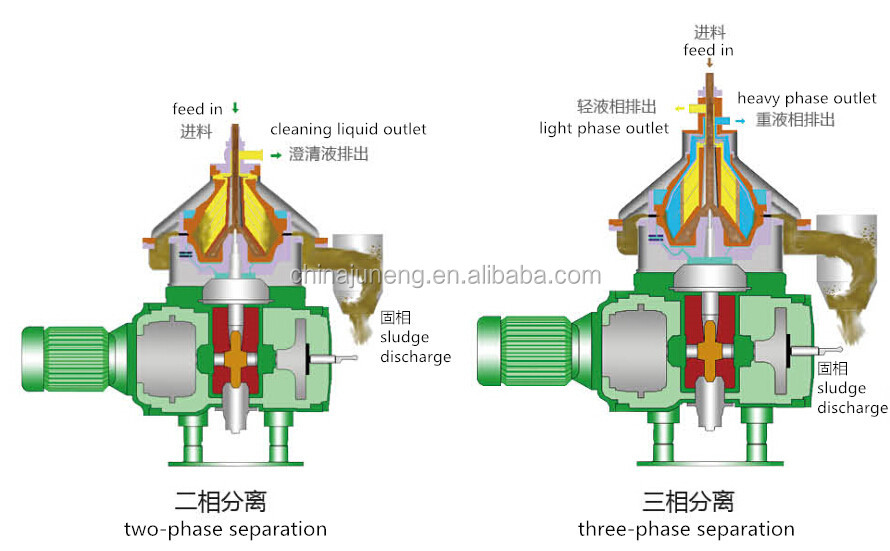

DHKY separator is the equipment which special for oil refining that is of high speed, stable, hermetic, efficient and fully automated. All parts & components contacting materials are made of stainless steel, can effectively minimize chemical reaction between the materials to be separated and part surface contacted. The separated light and heavy phase materials will be output by two centripetal pumps of different sizes. This machine is fed upper, so it has very low inlet pressure for materials.The hydraulic coupling and a pair of spiral speed increasing gears are used in the power transmission. The liquid is used to transmit power, which can not only increase the speed stably, but also protect the overload.

![]()

This separator is widely used for degumming, desoaping and water washing in vegetable oil continuous refining process, is one of the best equipment for modern oil refining. Meanwhile, it is also applicable for separating suspension liquid e.g. two liquids, liquid and solid that have different specific gravities in such industries as light industry, chemical, medicine and food, etc.

2.Working principle

The separator extracts residue automatically with ring valve, during its operation, you can adjust the separating and residue-extracting periods as well as other parameters (e.g. extraction time and interval, etc.) depending on the materials and requirements on finished oil. The separator is controlled by PLC, it’s easy and simple to operate, the display is straightforward, is highly automated. The trace residue in oil will also be discharged outside completely in the separation, this has greatly reduced the labor of workers for stopping and cleaning the drum, as well as economical loss due to shutdown.

ll parts & components contacting materials are made of stainless steel, can effectively minimize the corrosion from the materials to be separated, and meet hygienic requirements for food.

The separator bowl has gone through precise dynamic balance, it can run steadily, with low vibration and noise at operation.

The separator is equipped with an automatic control cabinet. It consist of an industrial computer and auto overload protector, is highly automated, highly adaptive to change in process, easy to adjust, can greatly reduce the operation labor of workers.

Our company has set-up a first class laboratory for Chemical composition analysis, metallographic analysis, spectrum analysis, performance analysis, radiographinc inspection, magnetism inspecion, ultra-sonic inspection and etc. This is to imply with the latest adva nce instrumentationss and rigorous working attitude to ensure every part of product is stable and reliable.

Juneng Group is a large scale manufacturer of industrial products in China. This group principally engaged with the in-house research & development as well as manufacturing of various industrial filters, separators , centrifuges and pumps.

![]()